Publication RENR2696-00 © Proprietary information of Perkins Engines Company Limited 2004, all rights reserved. The information is correct at the time of print. Published by Technical Publications. Perkins Engines Company Limited, Peterborough, PE1 5NA, England

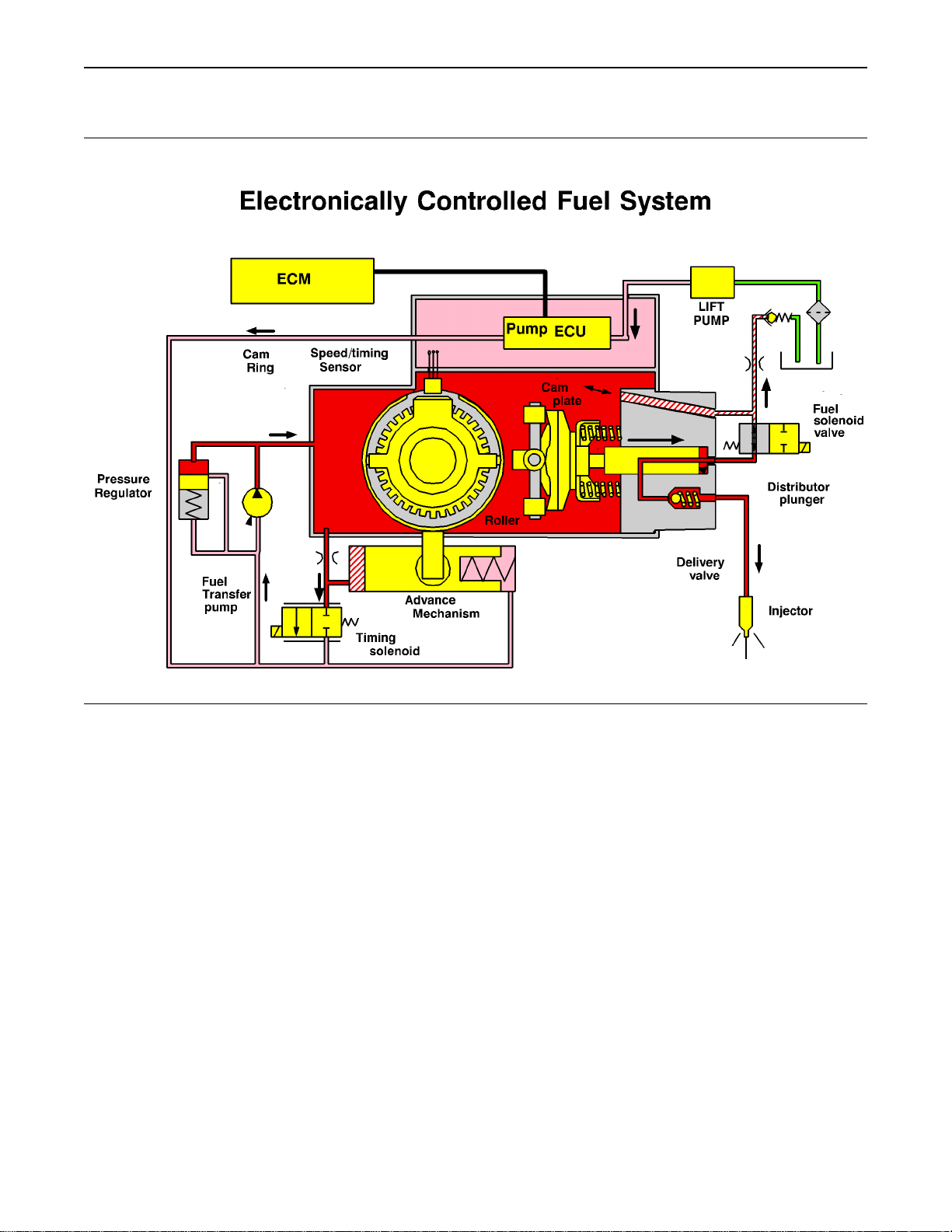

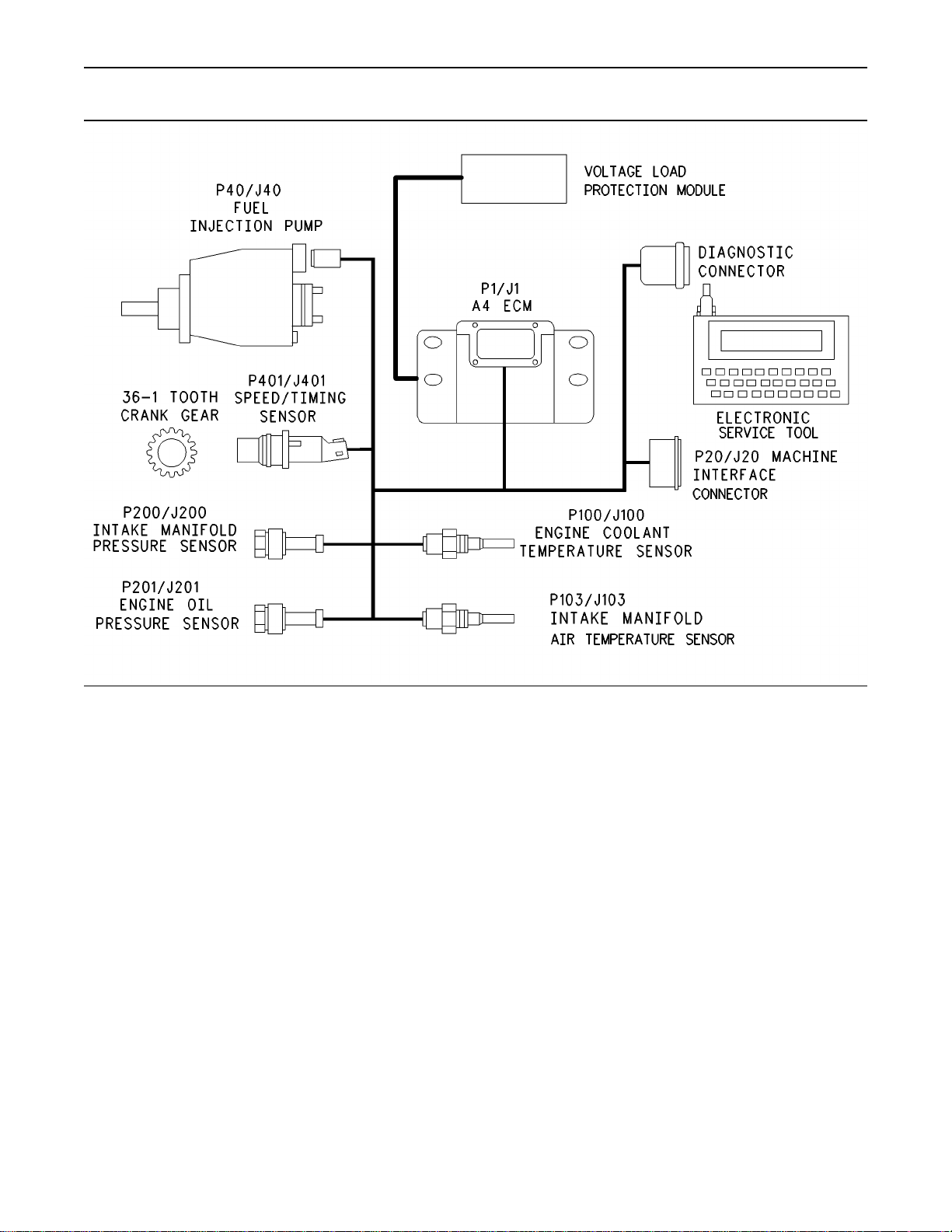

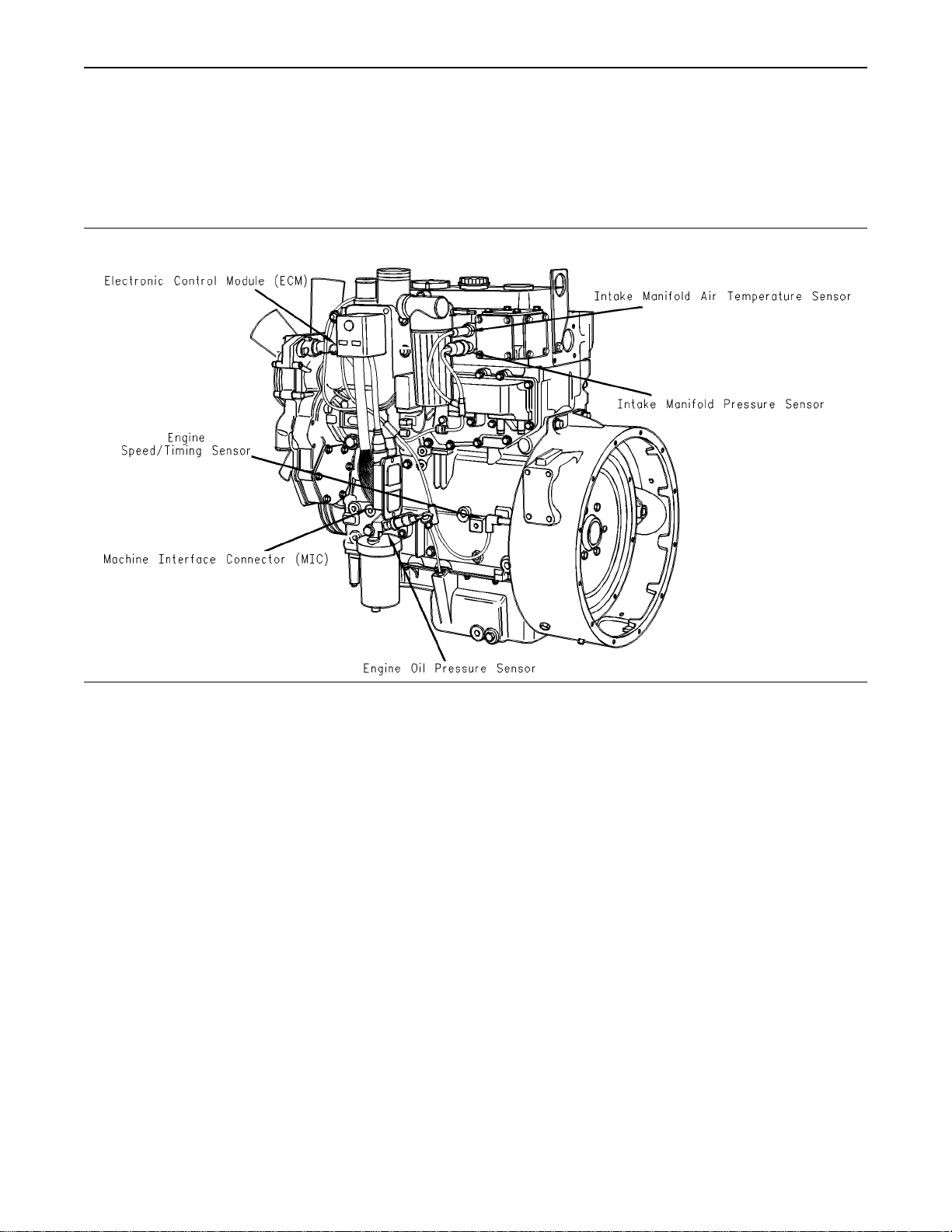

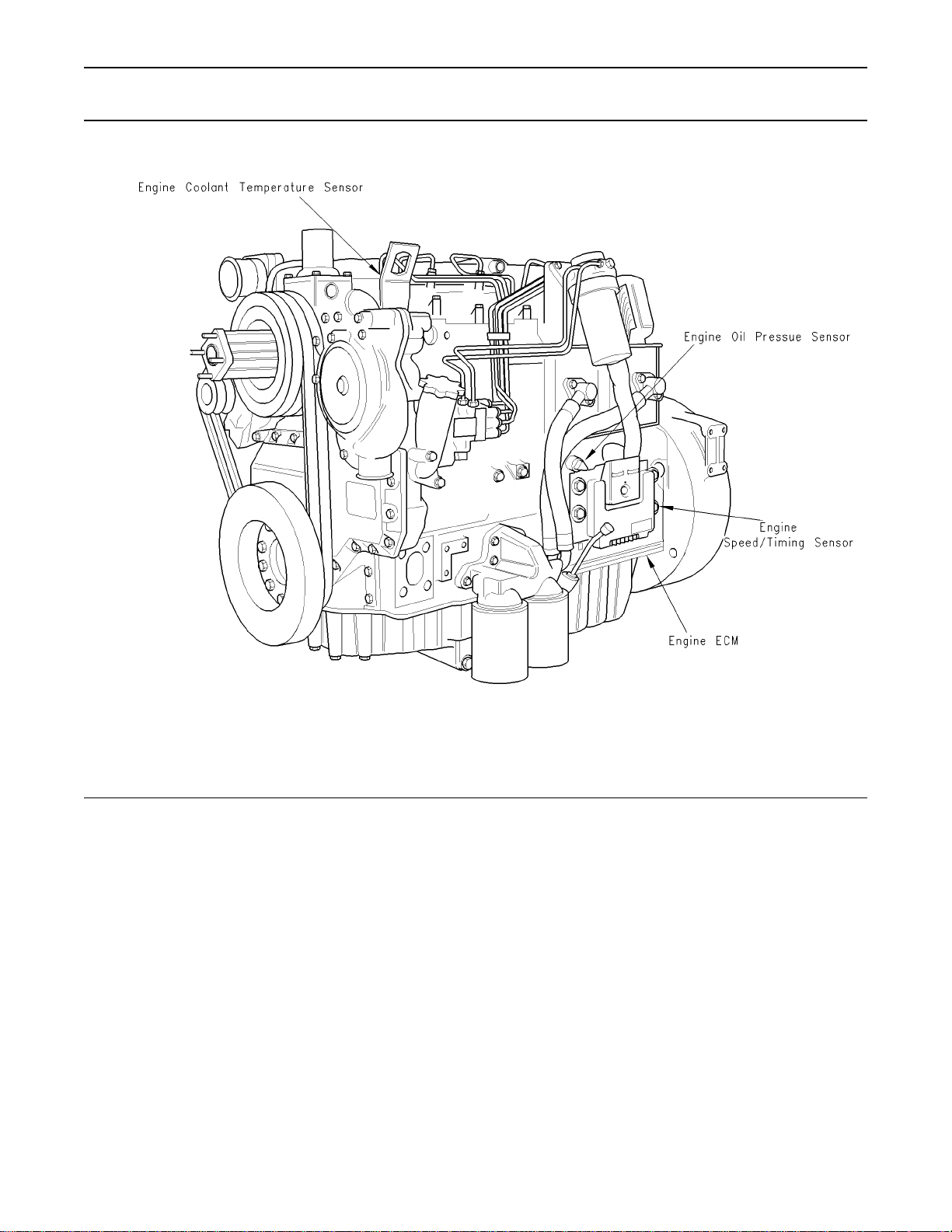

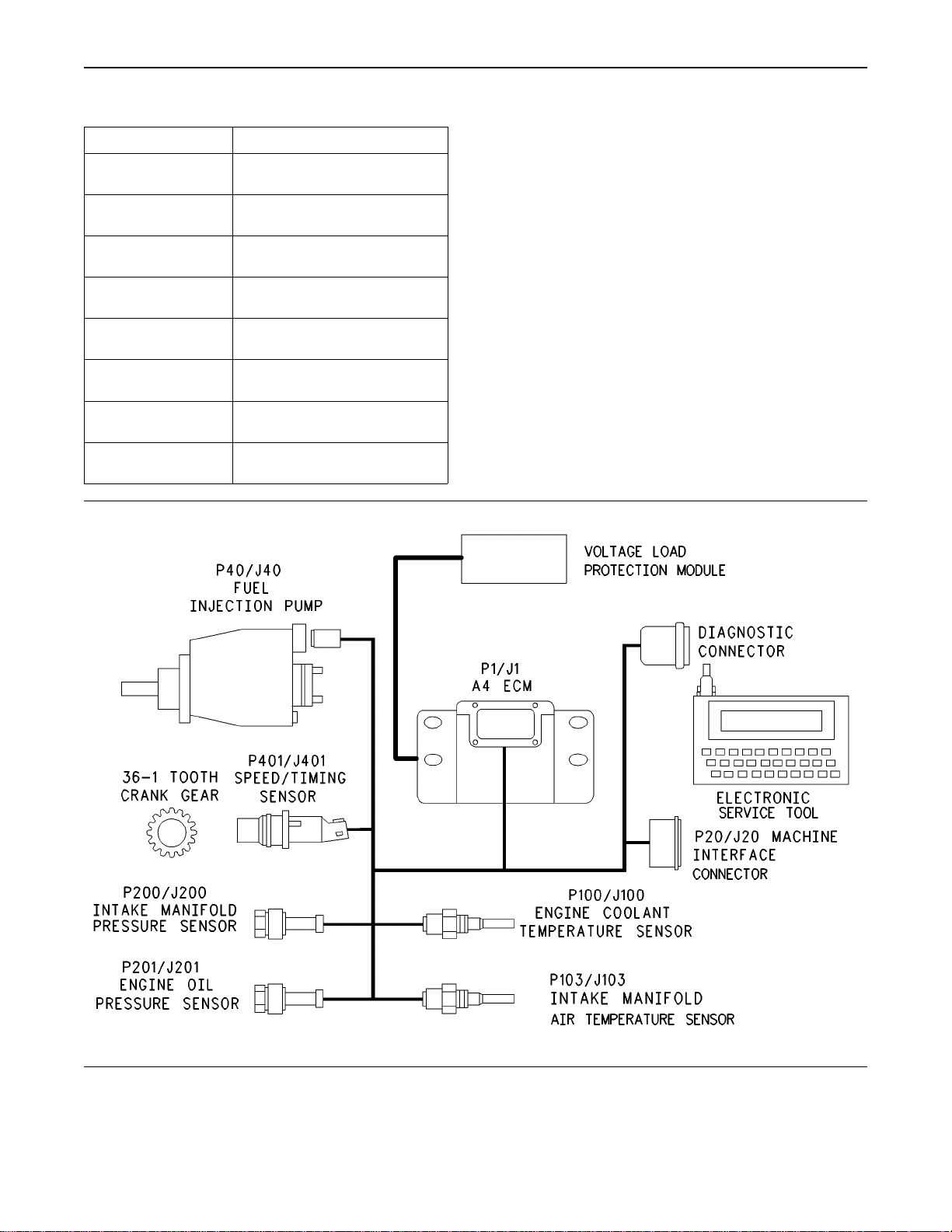

The 1104 models RF, RH, RK and 1106 model VK engines were designed for electronic control. The engines include an Electronic Control Module (ECM), a fuel injection pump that is electronically controlled, and a collection of engine sensors. The ECM controls the engine operating parameters through the software within the ECM and the inputs from the various sensors. The software contains parameters that control the engine operation. The parameters include all of the operating maps and customer selected parameters.

Troubleshooting Section

The electronic system consists of the Electronic Control Module (ECM), the engine sensors, and the Machine Interface Connector (MIC). The ECM is the computer. The personality module is the software for the computer. The personality module contains the operating maps. The operating maps define the following characteristics of the engine:

Horsepower Torque curves Engine speed (rpm) Engine GovernorThe electronic controls determine the injection timing and the amount of fuel that is delivered to the cylinders. These decisions are based on the actual conditions and the desired conditions at any given time.

The governor compares the desired engine speed to the actual engine speed. The actual engine speed is determined through the crankshaft position sensor. If the desired engine speed is greater than the actual engine speed, the governor injects more fuel in order to increase engine speed.

Timing ConsiderationsOnce the governor has determined the amount of fuel that is required, the governor must determine the timing of the fuel injection. Fuel injection timing is determined by the ECM after considering input from the following components:

Engine coolant temperature sensor The sensor for the intake manifold air temperature The sensor for the intake manifold pressure

At start-up, the ECM determines the top dead center position of the number 1 cylinder from the speed/timing sensor in the fuel injection pump. The ECM decides when fuel injection should occur relative to the top dead center position. The ECM provides the signal to the fuel injection pump spill valve which stops fuel flow to the low pressure side. The ECM then forces fuel to flow to the fuel injector nozzles at the desired time. The ECM adjusts timing for the best engine performance, the best fuel economy and the best control of exhaust emissions. Actual timing cannot be viewed with an electronic service tool. Also, the desired timing cannot be viewed with an electronic service tool.

Fuel InjectionThe personality module inside the ECM sets certain limits on the amount of fuel that can be injected. The FRC Limit is a limit that is based on intake manifold air pressure and engine rpm. The FRC Limit is used to control the air/fuel ratio in order to control the engine ’ s exhaust emissions. When the ECM senses a higher intake manifold air pressure, the ECM increases the FRC Limit. A higher intake manifold air pressure indicates that there is more air in the cylinder. When the ECM increases the FRC Limit, the ECM allows more fuel into the cylinder.

The Rated Fuel Limit is a limit that is based on the power rating of the engine and on the engine rpm. The Rated Fuel Limit enables the engine power and torque outputs to conform to the power and torque curves of a specific engine model.

These limits are in the personality module and these limits cannot be changed. Diagnostic CodesWhen the ECM detects an engine problem, the ECM generates a diagnostic code. Also, the ECM logs the diagnostic code in order to indicate the time of the problem ’ s occurrence. The ECM also logs the number of occurrences of the problem. There are two types of diagnostic fault codes. There are fault codes and event codes.

Diagnostic Fault CodesDiagnostic fault codes are provided in order to indicate that an electrical problem or an electronic problem has been detected by the ECM. In some cases, the engine performance can be affected when the condition that is causing the code exists. More frequently, the operator cannot detect any difference in the engine performance.

If the operator indicates that a performance problem occurs, the diagnostic code may indicate the cause of the problem. Use either a laptop computer or a hand held diagnostic tool to access the diagnostic codes. The problem should then be corrected.

If the operator does not indicate a problem with the engine performance and a diagnostic code is logged by the ECM. This situation indicates that the ECM detected an abnormal engine condition, but the abnormal condition did not affect engine performance. In this situation, the system has no faults except when either of the following conditions exist:

There are several occurrences of the diagnostic code in a very short period of time. The ECM is indicating an active code at the present time. Diagnostic Event CodesDiagnostic event codes are used to indicate that some operational problem has been detected in the engine by the ECM. This does not indicate an electronic malfunction.

Programmable ParametersCertain parameters that affect the engine operation may be changed with electronic service tools. The parameters are stored in the ECM, and the parameters are protected from unauthorized changes by passwords. These parameters are System Configuration Parameters.

System Configuration Parameters are set at the factory. System Configuration Parameters affect emissions or power ratings within the engine. Factory passwords must be obtained and factory passwords must be used to change the System Configuration Parameters.

System Configuration Parameters are protected by factory passwords. Factory passwords are calculated on a computer system that is available only to Perkins distributors. Since factory passwords contain alphabetic characters, only an electronic service tool may change System Configuration Parameters. System Configuration Parameters affect the power rating or the emissions.

Refer to Troubleshooting, “ Programming Parameters ” and Troubleshooting, “ Factory Passwords ” .

Active Diagnostic Code – An active diagnostic code alerts the operator or the service technician that an electronic system malfunction is currently present. Refer to the term “ Diagnostic Code ” in this glossary.

Alternating Current (AC) – Alternating current is an electric current that reverses direction at a regular interval that is reoccurring.

Before Top Dead Center (BTC) – BTDC is the 180 degrees of crankshaft rotation before the piston reaches the top dead center position in the normal direction of rotation.

Boost Pressure (Engines that are turbocharged) –The difference between the turbocharger outlet pressure and atmospheric pressure is commonly referred to as boost pressure. The sensor for the intake manifold air pressure measures the amount of boost.

Breakout Harness – The breakout harness is a test harness that is designed to connect into the engine harness. This connection allows a normal circuit operation and the connection simultaneously provides a Breakout T in order to measure the signals.

Bypass Circuit – A bypass circuit is a circuit that is used as a substitute circuit for an existing circuit. A bypass circuit is typically used as a test circuit.

CAN Data Link – The CAN Data Link is a serial communications port that is used for communication with other microprocessor based devices. In this application, the CAN Data Link connects the ECM to the Electronic Fuel Injection Pump.

Code – Refer to “ Diagnostic Code ” or “ Event Code ” . Cold Mode – Cold mode is a mode for cold startingand for cold engine operation that includes timing that is retarded and low idle that is raised. This mode is used for engine protection, reduced smoke emissions and faster warm up time.

Communication Adapter Tool – The communication adapter provides a communication link between the ECM and the Electronic Service Tool.

Coolant Level Sensor – The coolant level sensor detects the absence or presence of coolant at the probe. The sensor then sends a signal to the ECM.

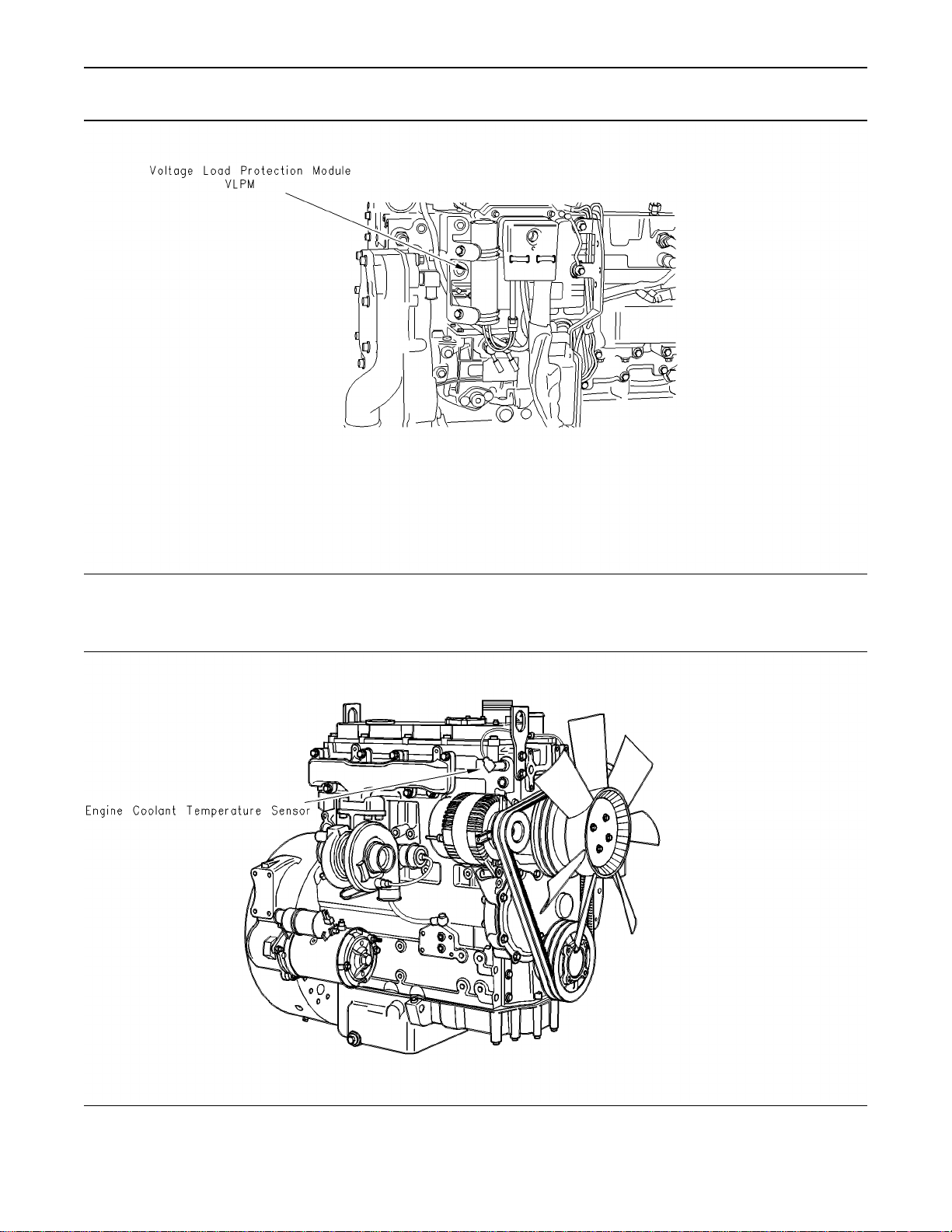

Coolant Temperature Sensor – The coolant temperature sensor detects the engine coolant temperature for cold mode operation and for Engine Monitoring.

Data Link – The Data Link is a serial communication port that is used for communication with other microprocessor based devices.

Desired Engine Speed – The desired engine speed is input to the electronic governor within the ECM. The electronic governor uses the signal from the throttle position sensor, the engine speed/timing sensor, and other sensors in order to determine the desired engine speed.

Diagnostic Code – A diagnostic code is sometimes referred to as a fault code. These codes indicate an electronic system malfunction.

Diagnostic Lamp – A diagnostic lamp is sometimes called the check engine light. The diagnostic lamp is used to warn the operator of the presence of an active diagnostic code.

Digital Sensor Return – The common line (ground) from the ECM is used as ground for the digital sensors.

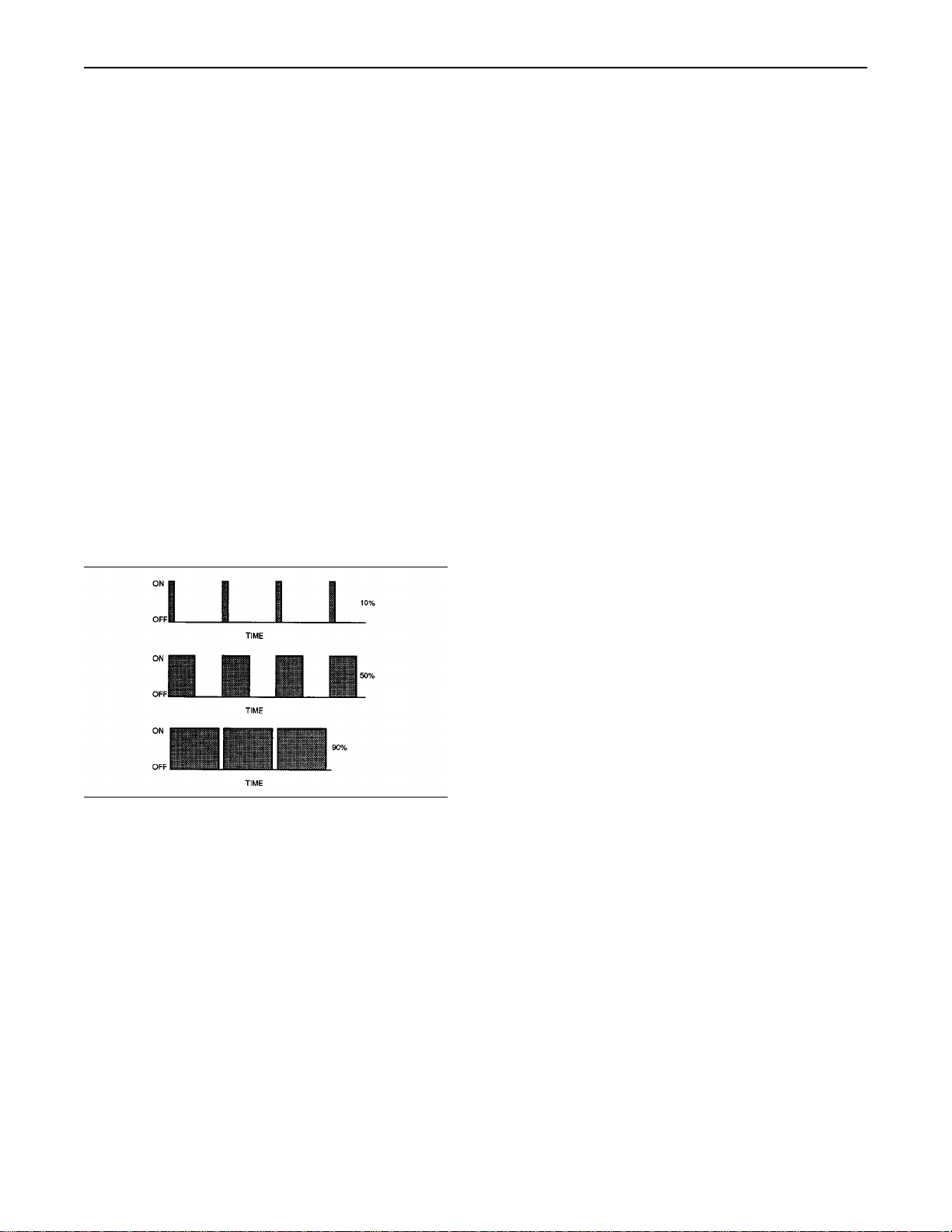

Digital Sensors – Digital sensors produce a pulse width modulated signal. Digital sensors are supplied with +8 VDC from the ECM.

Digital Sensor Supply – The +8 VDC supply from the ECM is used in order to power the digital sensors.

Direct Current (DC) – Direct current is the type of current that flows consistently in only one direction.

DT, DT Connector, or Deutsch DT – This is a type of connector that is used on Perkins engines. The connectors are manufactured by Deutsch.

Duty Cycle – Refer to “ Pulse Width Modulation ” . Electronic Engine Control – The electronic enginecontrol is a complete electronic system. The electronic engine control monitors the engine operation under all conditions. The electronic engine control also controls the engine operation under all conditions.

Component Identifier (CID) – The CID is a number that identifies the specific component of the electronic control system that has experienced a diagnostic code.

Electronic Service Tool – The electronic service tool allows a computer (PC) to communicate with the ECM.

control computer of the engine. The ECM provides power to the electronics. The ECM monitors data that is input from the sensors of the engine. The ECM acts as a governor in order to control the speed and the power of the engine.

Engine Monitoring – Engine Monitoring is the part of the electronic engine control that monitors the sensors. This also warns the operator of detected problems.

Engine Oil Pressure Sensor – The engine oil pressure sensor measures engine oil pressure. The sensor sends the signal to the ECM.

Engine Speed/Timing Sensor – The engine speed/timing sensor provides a variable amplitude and pulse width modulated signal to the ECM. The ECM interprets this signal as the crankshaft position and the engine speed.

Event Code – An event code may be activated in order to indicate an abnormal engine operating condition. These codes usually indicate a mechanical problem instead of an electrical system problem.

Failure Mode Identifier (FMI) – This identifier indicates the type of failure that has been experienced by the component. The FMI has been adopted from the SAE practice of J1587 diagnostics.

Flash Programming – Flash programming is the method of programming or updating an ECM with an electronic service tool over the data link instead of replacing components.

Fuel Ratio Control (FRC) – The FRC is a limit that is based on the control of the ratio of the fuel to air. The FRC is used for purposes of emission control. When the ECM senses a higher intake manifold air pressure (more air into the cylinder), the FRC increases the FRC Limit (more fuel into the cylinder).

Fuel Temperature Sensor – The fuel temperature sensor detects the fuel temperature. The ECM monitors the fuel temperature and the ECM adjusts the calculated fuel rate accordingly.

Full Load Setting (FLS) – The FLS is the number that represents the fuel system adjustment. This adjustment is made at the factory in order to fine tune the fuel system. The correct value for this parameter is stamped on the engine information ratings plate. This parameter must be programmed.

Harness – The harness is the bundle of wiring (loom) that connects all components of the electronic system.

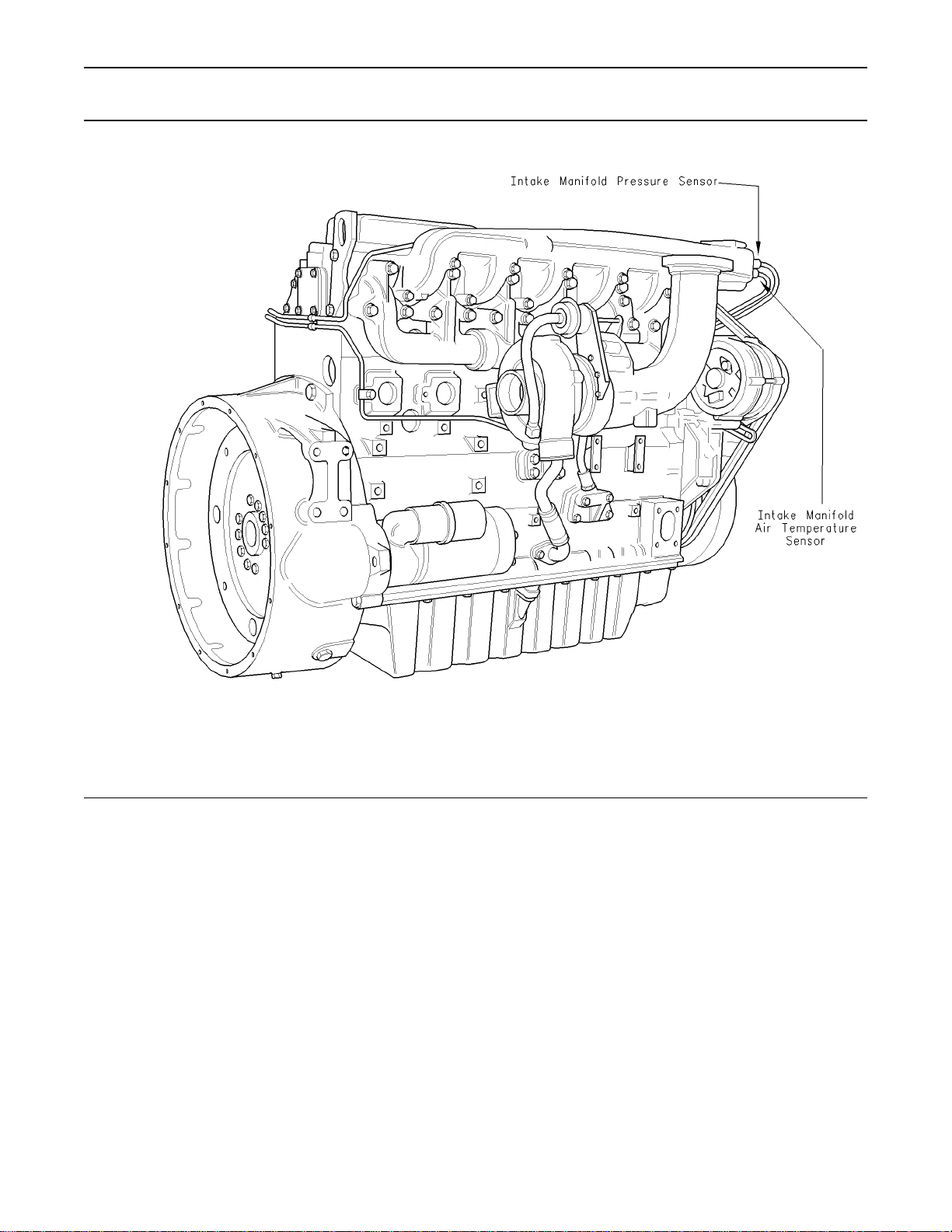

Hertz (Hz) – Hertz is the measure of electrical frequency in cycles per second.Intake Manifold Air Temperature Sensor – The intake manifold air temperature sensor detects the air temperature in the intake manifold. The ECM monitors the air temperature and other data in the intake manifold in order to adjust injection timing and other performance functions.

Intake Manifold Pressure Sensor – The air pressure in the intake manifold may be different to the air pressure outside the engine (atmospheric pressure). This difference in air pressure can be caused by variable air velocity within the manifold. The difference in pressure can also be caused by an increase in air pressure by a turbocharger (if equipped). The sensor for the intake manifold air pressure measures the difference between atmospheric pressure and the air pressure in the intake manifold.

Integrated Electronic Controls – The engine is designed with the electronic controls as a necessary part of the system. The engine will not operate without the electronic controls.

J1939 CAN Data Link – This data link is a SAE diagnostic communications data link that is used to communicate between the ECM and the electronic service tool.

Logged Diagnostic Codes – Logged diagnostic codes are codes which are stored in the memory. These codes are meant to be an indicator of possible causes for intermittent problems. Refer to the term “ Diagnostic Code ” in this glossary for more information.

MAB – This is a Bosch acronym for the fuel shutoff inside the “ VPM30 ” Fuel Injection Pump. The MAB is a signal wire from the ECM to the Fuel Injection Pump.

Open Circuit – An open circuit is a condition that is caused by an open switch, or by an electrical wire or a connection that is broken. When this condition exists, the signal or the supply voltage can no longer reach the intended destination.

Parameter – A parameter is a value or a limit that is programmable. This helps determine specific characteristics or behaviors of the engine.

Full Torque Setting (FTS) – The FTS is similar to the full load setting. This parameter must be programmed.

characters or a group of alphanumeric characters that is designed to restrict access to parameters. The electronic system requires correct passwords in order to change some parameters (Factory Passwords). Refer to Troubleshooting, “ Factory Passwords ” for more information.

Personality Module – This module is inside the ECM. The module contains all the instructions (software) for the ECM and the module contains the performance maps for a specific engine. The personality module may be reprogrammed through flash programming.

Power Cycled – Power cycled happens when power to the ECM is cycled: ON, OFF, and ON. Power cycled refers to the action of cycling the keyswitch from any position to the OFF position, and to the START/RUN position.

Pulse Width Modulation (PWM) – The PWM is a signal that consists of pulses that are of variable width. These pulses occur at fixed intervals. The ratio of “ TIME ON ” versus total “ TIME OFF ” can be varied. This ratio is also referred to as a duty cycle.

Short Circuit – A short circuit is a condition that has an electrical circuit that is inadvertently connected to an undesirable point. An example of a short circuit is a wire which rubs against a vehicle frame and this rubbing eventually wears off the wire insulation. Electrical contact with the frame is made and a short circuit results.

Signal – The signal is a voltage or a waveform that is used in order to transmit information typically from a sensor to the ECM.

Supply Voltage – The supply voltage is a constant voltage that is supplied to a component in order to provide the electrical power that is required for the component to operate. The power may be generated by the ECM or the power may be battery voltage that is supplied by the engine wiring.

System Configuration Parameters – System configuration parameters are parameters that affect emissions and/or operating characteristics of the engine.

Throttle Position – The throttle position is the interpretation by the ECM of the signal from the throttle position sensor or the throttle switch.

Illustration 3Rated Fuel Limit – This term indicates the maximum allowable fuel position (longest injection pulse). This position will produce rated power for this engine configuration.

Reference Voltage – Reference voltage is a regulated voltage and a steady voltage that is supplied by the ECM to a sensor. The reference voltage is used by the sensor to generate a signal voltage.

Sensor – A sensor is a device that is used to detect a change in pressure, temperature, or mechanical movement. The information that is detected is converted into an electrical signal.

Throttle Position Sensor – The throttle position sensor is an electronic sensor that is connected to an accelerator pedal or a hand lever. This sensor sends a PWM signal to the ECM that is used to calculate desired engine speed.

Throttle Switch – The throttle switch sends a signal to the ECM that is used to calculate desired engine speed.

Top Dead Center – Top dead center refers to the crankshaft position when the engine piston position is at the highest point of travel. The engine must be turned in the normal direction of rotation in order to reach this point.

Total Tattletale – The total tattletale is the total number of changes to all the parameters that are stored in the ECM.

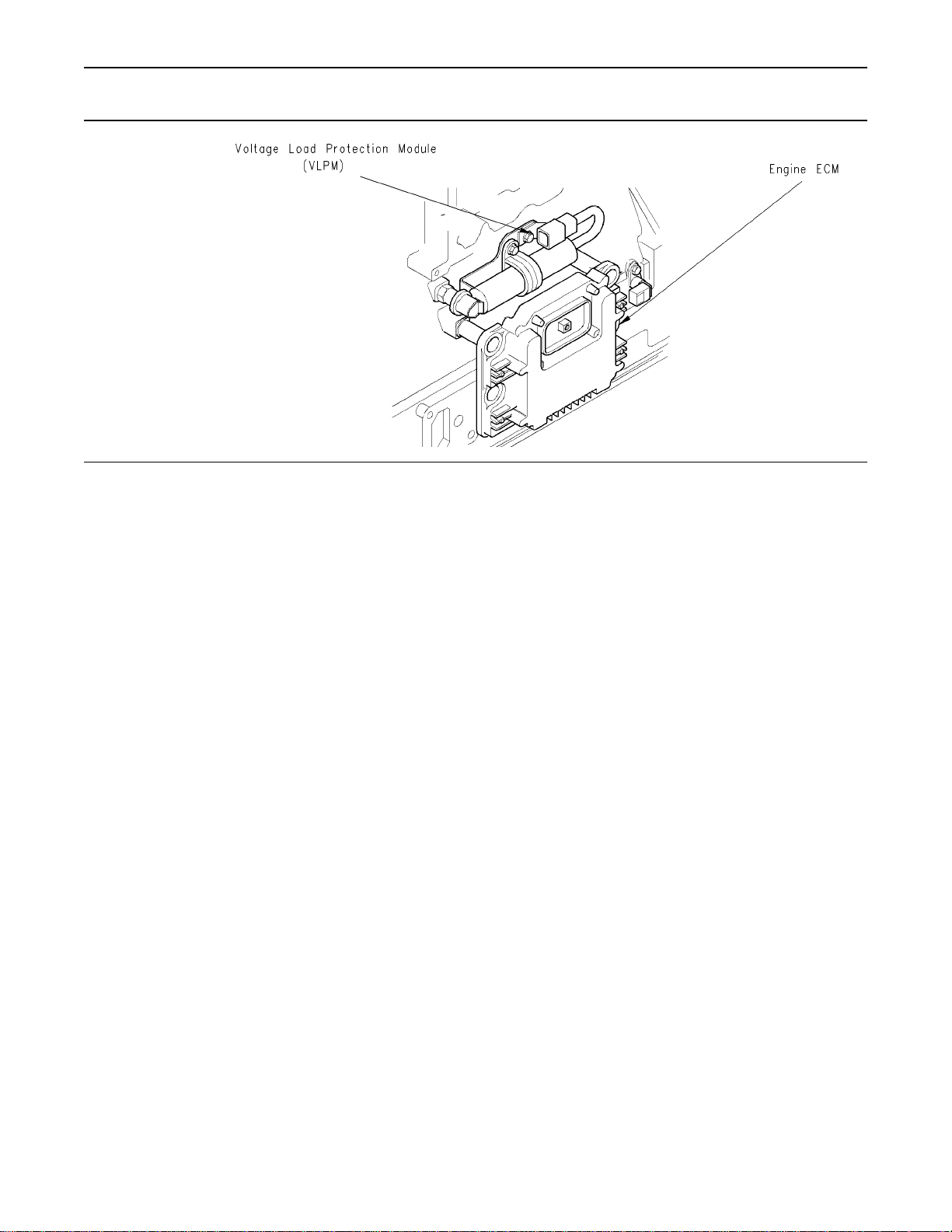

Voltage Load Protection Module ( “ VLPM ” ) – The “ VLPM ” monitors the voltage of the electronic system. The “ VLPM ” will eliminate any high voltage conditions that occur. The “ VLPM ” will protect the fuel injection pump from any high voltage conditions that could damage the pump.

Electronic Service Tools are designed to help the service technician with the diagnosis and repair of electronic engines. Several tools are available to assist the service technician.

Some of the included Diagnostic Functional Tests in this manual require two short jumper wires. The jumper wires are used to check the continuity of some wiring harness circuits by shorting two adjacent terminals together in a connector.

A long extension wire may also be needed to check the continuity of some wiring harness circuits. Electronic Service Tool The electronic service tool can display the following information: Parameters Event codes Diagnostic codes Required Electronic Service Tools for the Use of the Electronic Service Tool IBM compatible PC with 266 MHz Pentium processor 64 MB of RAM 400 MB of available hard drive space CD-ROM drive3.5" 1.44 MB floppy disk drive VGA monitor or display (800 x 600) Microsoft NT 4.0, 98, or 95 RS232 port with 16550AF UART

Recommended IBM compatible PC with 450 MHz Pentium III processor 128 MB of RAM 1 GB of available hard drive space 40X speed CD-ROM drive or 8X speed DVD drive3.5" 1.44 MB floppy disk drive Super VGA monitor or display (800 x 600) Microsoft NT 4.0, or 98 RS232 port with 16550AF UART

Windows 2000, XP, ME, Windows 2000, XP, ME, Description Engine configuration The electronic service tool can be used by the technician to perform the following functions: Diagnostic tests Sensor calibrations Flash programming Set parameters The following components are required to use the electronic service tool to service the engine.

If you are having problems with the software, you can contact the Perkins Service Systems Support Center.

Optional Service Tools The following table contains service tools that may be helpful to service the engine. Optional Service Tools Part Number DescriptionN/A N/A Suitable Breakout T (70 pin) N/A Suitable Crimp Tool N/A Suitable Cylinder Pressure Indicator N/A Suitable Battery Load Tester

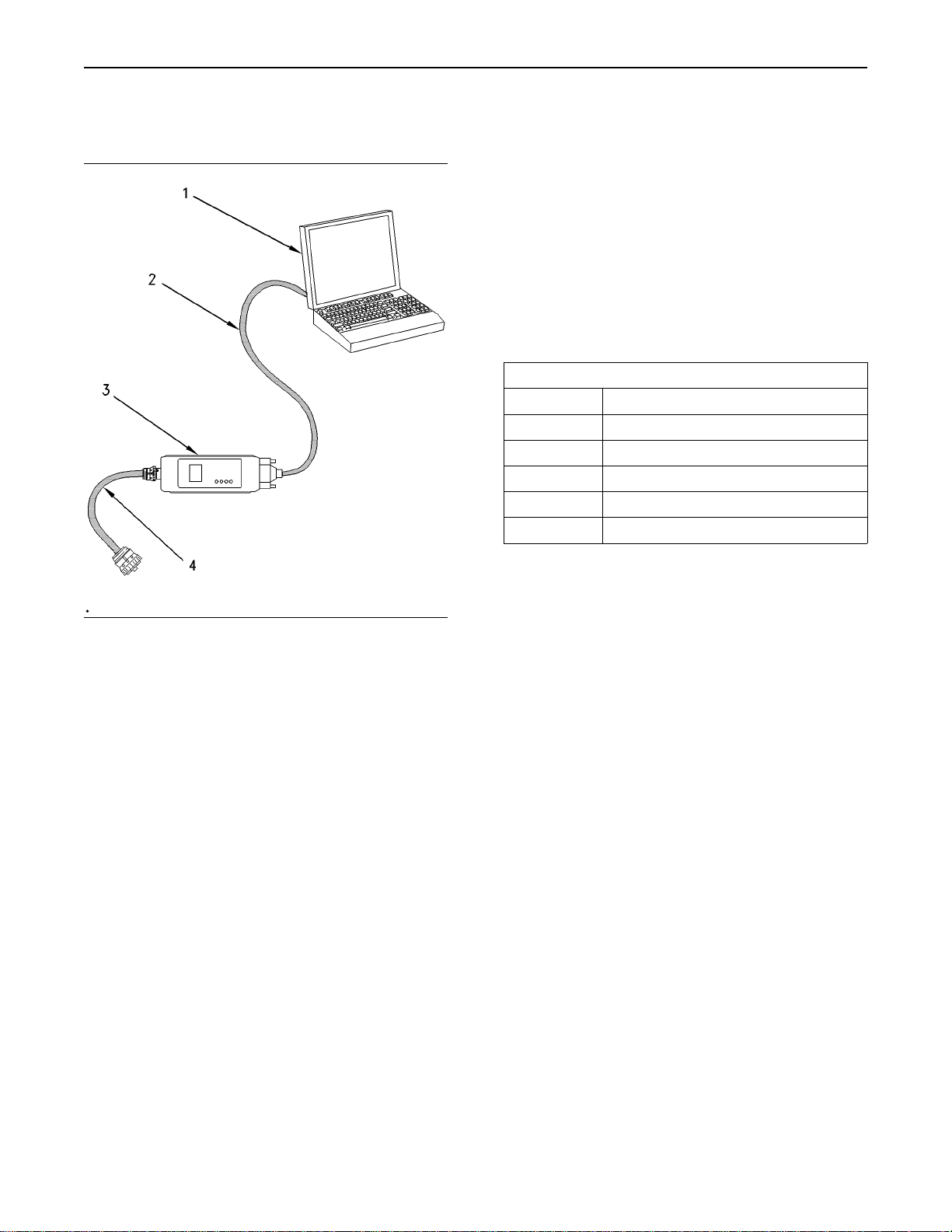

Suitable Digital Multimeter Illustration 4 (1) Personal computer (PC) (2) Adapter Cable (Computer Serial Port) (3) Communication Adapter II (4) Adapter Cable Assembly Note: Items (2), (3), and (4) are part of the Communication Adapter II Gp. Use the following procedure to connect the Electronic Service Tool and the Communication Adapter II. 1. Turn the keyswitch to the OFF/RESET position. If the keyswitch is not placed in the OFF/RESET position, the engine may start. 2. Connect cable (2) between the “ COMPUTER ” end of communication adapter (3) and the RS232 serial port of PC (1). 3. Connect cable (4) between the “ DATA LINK ” end of communication adapter (3) and the service tool connector. 4. Turn the keyswitch to the ON position. If theelectronic service tool and the communication adapter do not communicate with the ECM, refer to Troubleshooting, “ Electronic Service Tool Will Not Communicate With ECM ” .

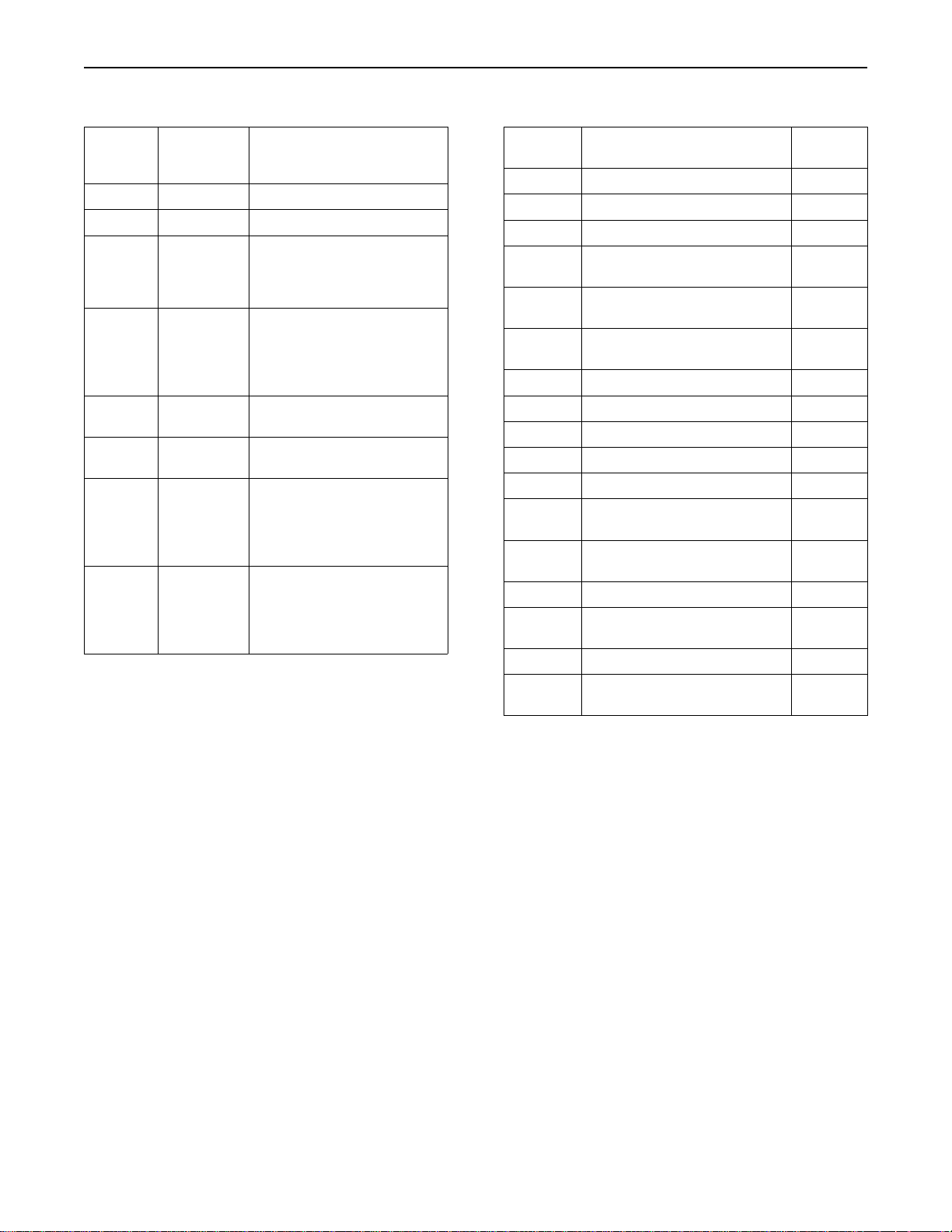

Diagnostic CodesThis list identifies the respective faults for the CID FMI and the J Code FMI codes. The CID FMI codes are displayed on a laptop computer. The J Code FMI codes are displayed on a Diagnostic Code Reader. The Diagnostic Code Reader is also known as the Hand Held Tool.

The Component Identifier (CID) is a number that identifies the specific component that caused a diagnostic code to be logged.

The Failure Mode Identifier (FMI) is a number that indicates the type of failure that has been experienced by the component.

The J1939 Code is another system that identifies the specific component that caused a diagnostic code to be logged.

Note: Event codes are not supported by J1939 numbers. Event codes use (CID) and (FMI) numbers. The following (FMI) numbers 0, 1, 15, 16, 17, and 18 are used for event codes.

0041 03 0041 04 0091 02 0091 03 0091 04 0091 08 0091 12 0100 03 0100 04 0100 10 0102 03 0102 04 0102 10 0105 03 0105 04 0110 03 0110 04 0168 02 0174 02 0247 09 0253 02 0262 03 0262 04 0266 02 0267 02 0320 02 0320 11 0321 02 0342 02 0590 02 0774 02 0774 03 0774 04 0774 08 0774 12 1627 03 1639 09 1684 00

J Code FMI Code Fault DescriptionJ0678 03 8V Sensor Power Supply, voltage more than normal J0678 04 8V Sensor Power Supply, voltage less than normal J0091 02 Throttle Demand Sensor, erratic or intermittent J0091 03 Throttle Demand Sensor, open circuit or shorted high J0091 04 Throttle Demand Sensor, shorted low J0091 08 Throttle Demand Sensor, abnormal signal J0091-12 Throttle Demand Sensor, power supply failure J0100 03 Engine Oil Pressure Sensor, open circuit or shorted high J0100 04 Engine Oil Pressue Sensor, shorted low

Engine Oil Pressure Sensor, power supply open circuit J0102 03 Intake Manifold Pressure Sensor, open circuit or shorted high J0102 04 Intake Manifold Pressure Sensor, shorted low

Intake Manifold Pressure Sensor, power supply open circuit J0105 03 Intake Manifold Temperature Sensor, open circuit or shorted high J0105 04 Intake Manifold Temperature Sensor, shorted low J0110 03 Engine Coolant Temperature Sensor, open circuit or shorted high J0110 04 Engine Coolant Temperature Sensor, shorted low J0168 02 Battery Voltage, intermittent or incorrect J0174 02 Fuel Temperature Sensor, erratic or intermittent J0639 09 J1939 Datalink, abnormal update J0234 02 Incorrect ECM Software J0620 03 5V Sensor Power Supply, voltage more than normal J0620 04 5V Sensor Power Supply, voltage less than normal

Crank without injection, switch state incorrectExternal Stop Switch, data erratic or incorrect J0637 02 Speed and Timing Sensor, intermittent loss of signal J0637 11 Speed and Timing Sensor, loss of signal

Diagnostic Reset Switch, intermittent or incorrect J0723 02 Speed and Timing Sensor No.2, intermittent signal

ECM identified missing timing pulse Throttle Demand Sensor No.2, erratic or intermittent Throttle Demand Sensor No.2, open circuit or shorted high Throttle Demand Sensor No.2, shorted low Throttle Demand Sensor No.2, abnormal signal Throttle Demand Sensor No.2, power supply failure Fuel Pump Relay, did not turn offMachine Security System Module, abnormal update J1077 00 Fuel Injection Pump, fuel temperature more than normal

1684 02 1684 03 1684 04 1684 05 1684 07 1684 08 1684 09 1684 10 1684 11 1684 12 1684 14 1690 08 1743 02 1894 02 1895 02

Event Code CID FMI CodeE015 E016 E017 E025 E027 E039 E040 E054 E056 E100 E190 E442 Engine Failed To Stop With A No-Fuel Command E883 Engine Failed To Stop When Fuel Solenoid Disengaged

J1077 02 Fuel Injection Pump, software failure J1077 03 Fuel Injection Pump, fuelling fault J1077 04 Fuel Injection Pump, supply voltage fault J1077 05 Fuel Injection Pump, invalid pulse width J1077 07 Fuel Injection Pump, mechanical fault J1077 08 Fuel Injection Pump, crankshaft reference fault J1077 09 Fuel Injection Pump, CAN fault J1077 10 Fuel Injection Pump, fuel shutoff signal error J1077 11 Fuel Injection Pump, internal sensor fault J1077 12 Fuel Injection Pump, device failure J1077 14 Fuel Injection Pump, no communications

Analogue Speed Control, signal abnormal Engine Mode Selection Switch State, invalid state Set Speed Control Disengage Switch, invalid state Set Speed Control Speed Toggle Switch, invalid state 110 16 110 00 110 15 105 16 105 15 100 18 100 01 174 16 174 15 100 17 190 15 High Engine Coolant Temperature Derate High Engine Coolant Temperature Sutdown High Engine Coolant Temperature Warning High Intake Air Temperature Derate High Intake Air Temperature Warning Low Engine Oil Pressure Derate Low Engine Oil Pressure Shutdown High Fuel Temperature Derate High Fuel Temperature Warning Low Engine Oil Pressure Warning Engine Overspeed Warning Troubleshooting Section Indicator LampsSome engine applications are equipped with Indicator Lamps. Indicator lamps can be used as a diagnostic aid. There are two lamps. One lamp has an orange lens and the other lamp has a red lens.

These indicator lamps can be used in two ways: The indicator lamps can be used to identify thecurrent operational status of the engine. The indicator lamps can also be used to indicate that the engine has a fault. This system is automatically operated via the ignition switch.

The indicator lamps can be used to identify active diagnostic codes. This system is activated by pressing the Flash Code button.

Each lamp will be illuminated in a combination of ways in order to identify the engine ’ s operational status. The lamps will also be illuminated in a combination of ways to indicate if the engine has a fault. These combinations of illuminated lamps have the following meanings:

The status of the lamps before the engine is cranked. This also acts as a lamp check.When the ignition switch is turned ON, the lamps will be illuminated for 2 seconds. The lamps are then OFF unless the cold starting aid is required.

ON ON The lamps will be illuminated Refer to the The lamp status with the cold starting aid in operation and before the engine is cranked. for 2 seconds or the lamps will be illuminated until the engine is cranked. OFF The lamp will be OFF unless the cold starting aid is required. OFF OFF There are no apparent ON ON The lubricating oil pressure is low. This low oil pressure was measured after the set delay had expired. The status of the lamps after cranking has failed to start the engine. OFF OFF No faults were detected. ON OFF An electrical fault was OFF Flashing The engine was activated when a serious fault was detected. Other combinations of illuminated indicator lampThe following combinations of lamp status may also be exhibited when the engine is either running or when the engine has been shut down automatically.

The orange lamp will be illuminated until the engine is ready to be cranked. ON OFF The status of the lamps with Then OFF OFF This is the status of the the cold starting aid still operating. lamps while the engine is being cranked. The cold starting aid is no longer operating. This is the status of the lamps while the engine is being cranked.Unless there is a fault, the engine monitoring system will not illuminate the indicator lamps while the engine is being cranked. For example if there is a lack of lubricating oil pressure after the start delay is exceeded. This type of fault will cause the stop lamp for the engine to be illuminated.

engine to shut down or the engine has exceeded the conditions for a derate. There is also an electrical fault.

either the coolant temperature or the intake air temperature is high. The engine may be derated. Use the lamps to identify active diagnostic codes. 0041 0091 0100 0102 0174 0247 0253 0262 0320 0342 Description Flash 8 Volt Power Supply Throttle Position Sensor Engine Oil Pressure Sensor Intake Manifold Pressure Sensor Intake Manifold Air Temperature Sensor Engine Coolant TemperatureSensor Fuel Temperature Sensor J1939 Data Link Personality Module 5 Volt Power Supply Engine Speed/Timing Sensor Secondary Engine Speed

Sensor Secondary Throttle Position Sensor Fuel Injection Pump Mode Selector Switch for Engine Operation Cruise Control Status Switch Toggle Switch for Cruise Control Speed 517 154 157 135 165 514 416 516 141 142The indicator lamps can be used to identify an active code by flashing in a sequence that will identify the active code. The active code that is flashed by the indicator lamps is only the component identifier (CID). The indicator lamps cannot identify the fault with the component. The active code that is flashed by the indicator lamps is not a Failure Mode Identifier (FMI).

When the Flash Code feature is activated the indicator lamps will flash the codes of all active codes. Activation of the indicator lamps is achieved by cycling the keyswitch OFF and ON twice within 3 seconds.

There will be a delay of 2 seconds before the lamps start to flash the identity of any active code.An active CID with two digits will be flashed in the following sequence. There will be a number of flashes. The number of flashes will equal the first digit. There will be a delay before a second number of flashes. The second number of flashes will equal the second digit. For example, a CID code of 41 will be four flashes, a delay and the one flash. A three digit CID code will have two delays between the sequence of flashes. A four digit CID code will have three delays between the sequence of flashes.

Each flash of the lamp will be 0.5 seconds long. There will be a delay between each flash of 0.3 seconds.

After one active code has been identified there will be a delay of 5 seconds before the next active code is flashed.

The sequence of flashing the active codes may be restarted at any time by reactivating the cycling of the keyswitch.

Replacing the ECM Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life.The engine is equipped with an Electronic Control Module (ECM). The ECM contains no moving parts. Follow the troubleshooting procedures in this manual in order to be sure that replacing the ECM will correct the problem. Verify that the suspect ECM is the cause of the problem.

Note: Ensure that the ECM is receiving power and that the ECM is properly grounded before replacement of the ECM is attempted. Refer to Troubleshooting, “ Electrical Power Supply Circuit Test ” .

A test ECM can be used in order to determine if the ECM on the engine is faulty. Install a test ECM in place of the suspect ECM. Flash the personality module into the test ECM. Program the parameters for the test ECM. The parameters must match the parameters in the suspect ECM. Refer to the following test steps for details. If the test ECM resolves the problem, reconnect the suspect ECM. Verify that the problem returns. If the problem returns, replace the ECM.

Use the electronic service tool to read the parameters in the suspect ECM. Record the parameters in the suspect ECM. The personality module can be flashed into the new ECM. After the ECM is installed on the engine, the parameters must be programmed into the new ECM.

Note: When a new ECM is not available, you may need to remove an ECM from an engine that is not in service. The ECM must have the same serial number suffix. Ensure that the replacement ECM and the Personality Module Interlock Code match the suspect ECM. Be sure to record the parameters from the replacement ECM. Use the “ Copy Configuration ECM Replacement ” function in the electronic service tool.

NOTICE If the Personality Module and engine application are not matched, engine damage may result. Perform the following procedure in order to replace the ECM. 1. Connect the electronic service tool to the service tool connector. 2. Use the “ Copy Configuration ECM Replacement ”function from the electronic service tool. If the “ Copy Configuration ” is successful, proceed to Step 4 . If the “ Copy Configuration ” failed, proceed to Step 3 .

Note: You may want to record any Logged Faults and Events for your records. 3. Record the parameters. Record all of theparameters on the “ Main Configuration ” screen. Also, record all of the parameters on the “ Throttle Configuration ” screen and on the “ Mode Configuration ” screen.

Note: If the parameters cannot be read, the parameters must be obtained elsewhere. Some parameters are stamped on the engine information plate, but most parameters must be obtained from the factory.

4. Remove the ECM. a. Turn the keyswitch to the OFF position. b. Turn the battery disconnect switch to the OFF c. Slacken the 4 mm Allen head screw and disconnect the ECM 70-pin (P1/J1) connectors. d. Remove the mounting bolts from the ECM. e. Disconnect the grounding strap from the ECM. 5. Install the replacement ECM.

installed correctly. The rubber grommets are used to protect the ECM from excessive vibration. The ECM should be able to drift in the rubber grommets.

c. Install the ground strap for the ECM on the d. Reconnect the J1/P1 70 Pin connector to the ECM. Tighten the Allen head screw on the connectors to a torque of 6 N · m (55 lb in). 6. Download the Flash file. a. Connect the electronic service tool to the service connector. b. Select “ WinFlash ” from the “ Utilities ” menu of the electronic service tool. c. Select the appropriate file. 7. If it is necessary, use the electronic service toolto clear the rating interlock in the Personality Module. To clear the rating interlock, enter the factory password when the electronic service tool is first connected. Activating the “ Test ECM ” mode will also clear the rating interlock.

8. Use the electronic service tool to program the parameters. Perform the following procedure. a. If the “ Copy Configuration ” procedure wassuccessful, use the “ Copy Configuration, ECM Replacement ” function to load the configuration file into the ECM.

Diagnostic Code – When a problem with the electronic system is detected, the ECM generates a diagnostic code. This indicates the specific problem with the circuitry.

Diagnostic codes can have two different states:Active Code – An active diagnostic code indicates that an active problem has been detected. Active codes require immediate attention. Always service active codes prior to servicing logged codes.

Logged Code – Every generated code is stored in the permanent memory of the ECM. The codes are logged.

Event Code – An event code is generated by the detection of an abnormal engine operating condition. For example, an event code will be generated if the oil pressure is too low. In this case, the event code indicates the symptom of a problem.

Logged codes may not indicate that a repair is needed. The problem may have been temporary. The problem may have been resolved since the logging of the code. If the system is powered, it is possible to generate an active diagnostic code whenever a component is disconnected. When the component is reconnected, the code is no longer active. Logged codes may be useful to help troubleshoot intermittent problems. Logged codes can also be used to review the performance of the engine and the electronic system.

b. If the “ Copy Configuration ” procedure failed, configure the parameters individually. The parameters should match the parameters from step 2 . 9. Check for logged diagnostic codes. Factory passwords are required to clear Logged Events. Self-DiagnosticsThe Electronic Control Module (ECM) has the ability to detect problems with the electronic system and with engine operation. When a problem is detected, a code is generated. An alarm may also be generated. There are two types of codes:

Diagnostic

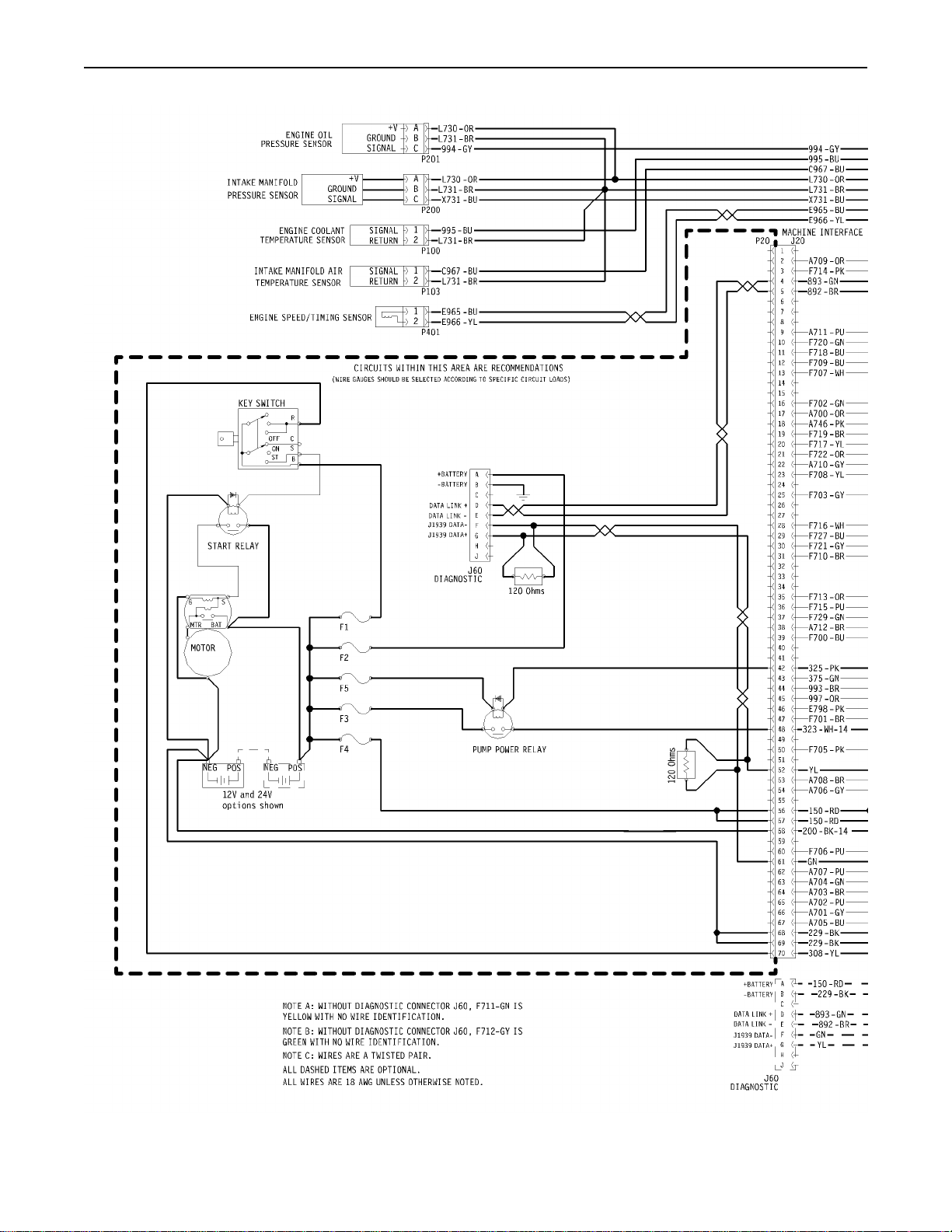

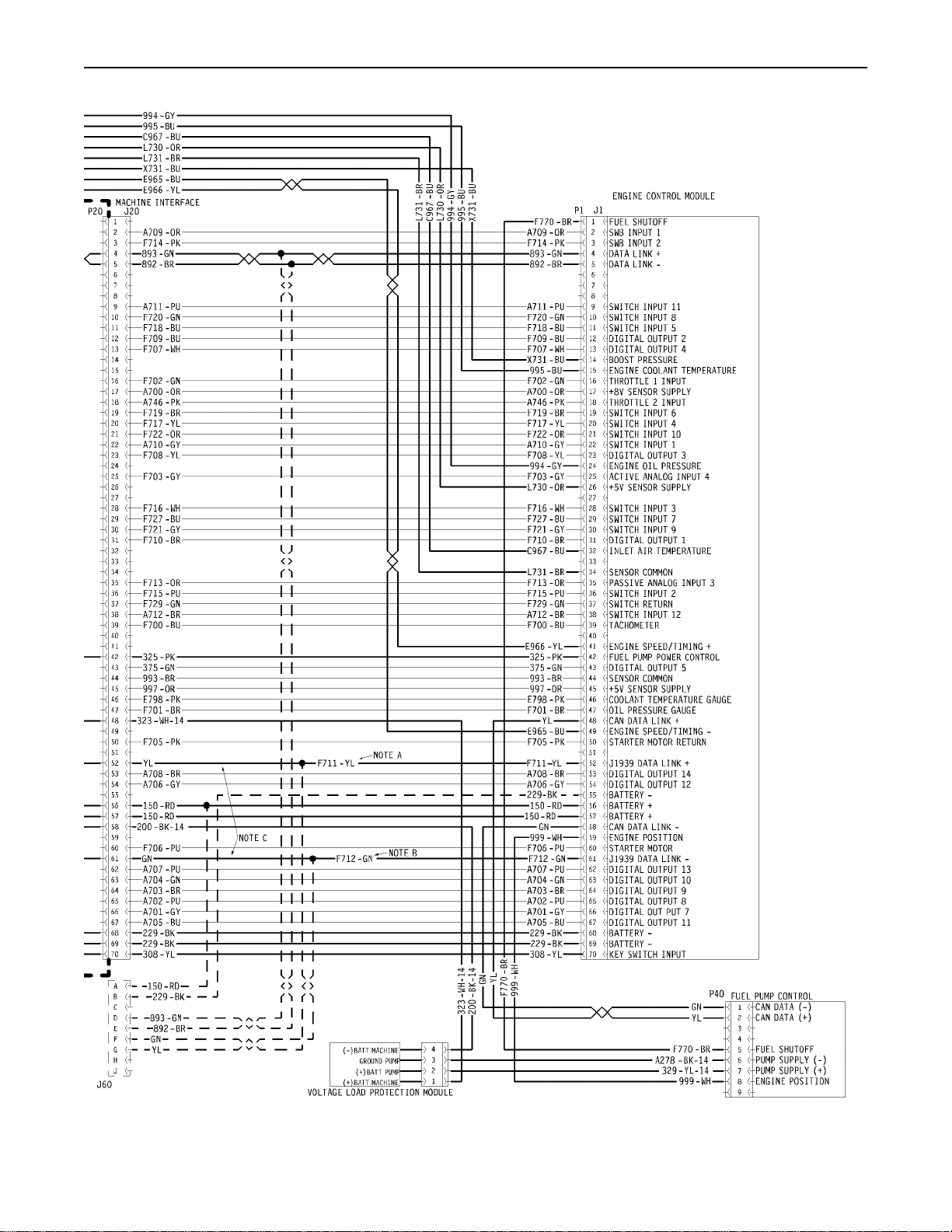

The wiring diagrams are revised periodically. The wiring diagrams will change with updates to the wiring harness. For the most current information, always check the revision number of the diagram. Use the diagram with the latest revision number.

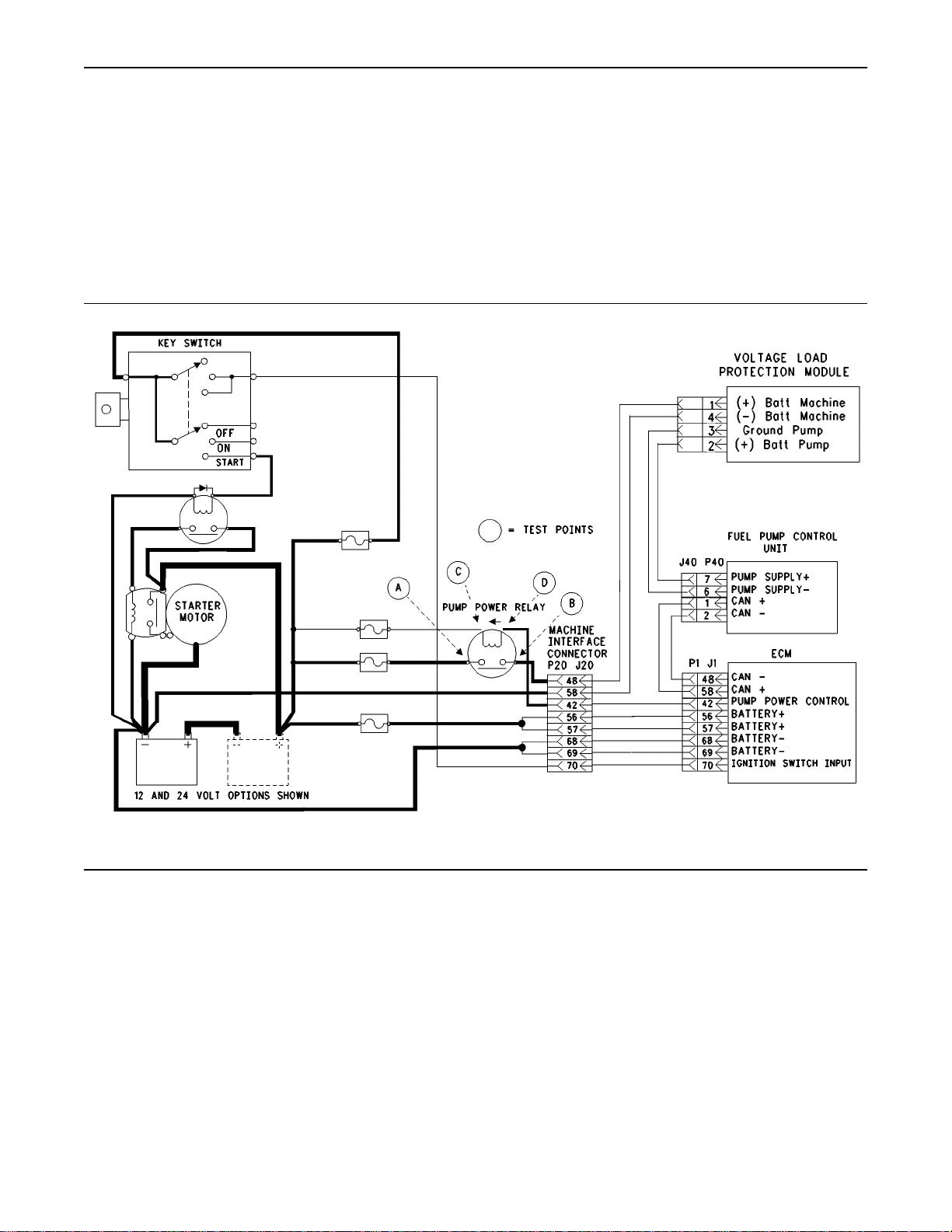

Illustration 12 Schematic for the fuel injection pump and ECM power supply

Note: Each terminal end of the J1939 CAN data link must be connected with a 120 ohm terminating resistor.

Note: Digital outputs 7,8,9,10,11,12,13, and 14 are only suitable for a 12 V system. Harness Wire IdentificationPerkins identifies all wires with eleven solid colors. The circuit number is stamped on the wire at a 25 mm (1 inch) spacing. Table 11 lists the wire colors and the color codes.

Ta bl e 1 1 Color Codes for the Harness Wire Color Code Color Color Code Color BK BR Brown BU Blue RD Red PU Purple OR Orange GY Gray YL Yellow WH White Black GN Green Troubleshooting SectionFor example, a wire identification of F702-GN on the schematic would signify a green wire with the circuit number F702. F702-GN identifies the power supply for the 8 V throttle sensor.

Note: Always replace a harness wire with the same gauge of wire and with the same color code.

The electronic service tool can be used to view certain parameters that can affect the operation of the engine. The electronic service tool can also be used to change certain parameters. The parameters are stored in the Electronic Control Module (ECM). Some of the parameters are protected from unauthorized changes by passwords. Parameters that can be changed have a tattletale number. The tattletale number shows if a parameter has been changed.

Factory PasswordsNote: The old interlock code is required to change the interlock code on a used ECM. A new interlock code is also required to change the interlock code on a used ECM.

The electronic service tool screen for factory passwords will display the following parameters: Serial number of the Electronic Control Module Engine serial number Serial number for the electronic service tool Reason Code Total Tattletale numberNote: The factory passwords may only be used for one programming session. A different set of factory passwords will be required after you exit the electronic service tool screen. A different set of passwords will be required to change information on another electronic service tool screen.

Customer PasswordsPasswords are part of a security system that helps to prevent unauthorized reprogramming of certain parameters. Passwords prevent unauthorized erasing of logged events. Passwords allow the factory to control access to engine calibration parameters. Passwords allow the customer to control access to certain programmable engine parameters.

Factory PasswordsFactory passwords are required to clear any event code. Factory passwords are required to change certain parameters such as Full Load Setting. The factory passwords restrict changes to authorized personnel. When the correct factory passwords have been entered, the changes can then be made.

In order to obtain the proper factory passwords, certain information must be given to an authorized Perkins distributor. Since the factory passwords contain alphabetic characters, the electronic service tool can be used to perform this function. In order to obtain the factory passwords, proceed as if you already have the factory passwords. At some point, if the factory passwords are actually needed, the electronic service tool will request the factory passwords and the electronic service tool will display the information that is required to obtain the factory passwords.

Customer Passwords allow the customer to restrict access to parameters that are programmable by the customer. The customer passwords cannot be longer than eight characters. The customer has the option of entering one or two customer passwords.

Note: If the owner loses the owner ’ s customer passwords, the owner will not be able to program parameters that are protected by customer passwords. By using factory passwords, one can read customer passwords. Then use those customer passwords to program parameters that have been protected by customer passwords.

Flash Programming Flash Programming – This is a method of programming or updating the personality module in an ECM.The electronic service tool can be utilized to flash a new personality module into the ECM. The flash is accomplished by transferring the data from a PC to the ECM.

3. When an ECM has been detected, the “ ECM Selector ” window will appear. Select the appropriate ECM that needs to be flashed and press “ Browse ” .

The “ Flash File Selection ” window will appear.4. The flash files are located on a disk drive and in a directory. Select the correct disk drive and the correct directory from “ Drives ” and “ Directories ” on the electronic service tool.

Troubleshooting Section A list of flash files will appear.5. Select the correct file from the list of flash files. Read the “ File Info ” and the “ Description ” in order to verify that the correct file is selected. Select “ OK ” .

6. Select the “ Begin Flash ” button in order to program the personality module. When the flash is completed, this message will appear: “ Flash Completed Successfully ” . 7. Start the engine and check for proper operation. a. If a diagnostic code of 253-02 Incorrect ECM Software is generated, program any parameters that were not in the old personality module. b. Access the “ Configuration ” screen underthe “ Service ” menu in order to determine the parameters that require programming. Look under the “ Tattletale ” column. All of the parameters should have a tattletale of 1 or more. If a parameter has a tattletale of 0, program that parameter.

“ WinFlash ” Error MessagesIf you receive any error messages during flash programming, click on the “ Cancel ” button in order to stop the process. Access the information about the “ ECM Summary ” under the “ Information ” menu. Make sure that you are flashing the correct file for your engine.